In the intricate world of jewelry manufacturing, where precision and creativity collide, Computer-Aided Design (CAD) has emerged as the unsung hero. Gone are the days when artisans relied solely on hand-drawn sketches to bring their visions to life. Today, CAD designing is the beating heart of the jewelry-making process, propelling the industry into a new era of innovation and efficiency. Many Indian factories are just as sophisticated in digital design as they are in expert craftsmanship, and with computer-aided design (CAD) capabilities that rival the best in the world, Indian partners give global brands access to leading-edge sustainable collections.

By tapping into CAD strengths of Indian jewelry manufacturers, forward-thinking jewelry companies can capitalize on virtual design for trending looks, smarter production, and optimized profits. Read on to learn how to leverage these capabilities.

Digital Design for On-Trend Collections

India’s exceptional CAD expertise enables speedy development of collections that align with the latest fashion trends. Their digitally-driven process looks like this:

– Cloud collaboration – Global design teams upload inspiration images, color palettes, and conceptual sketches to shared cloud platforms.

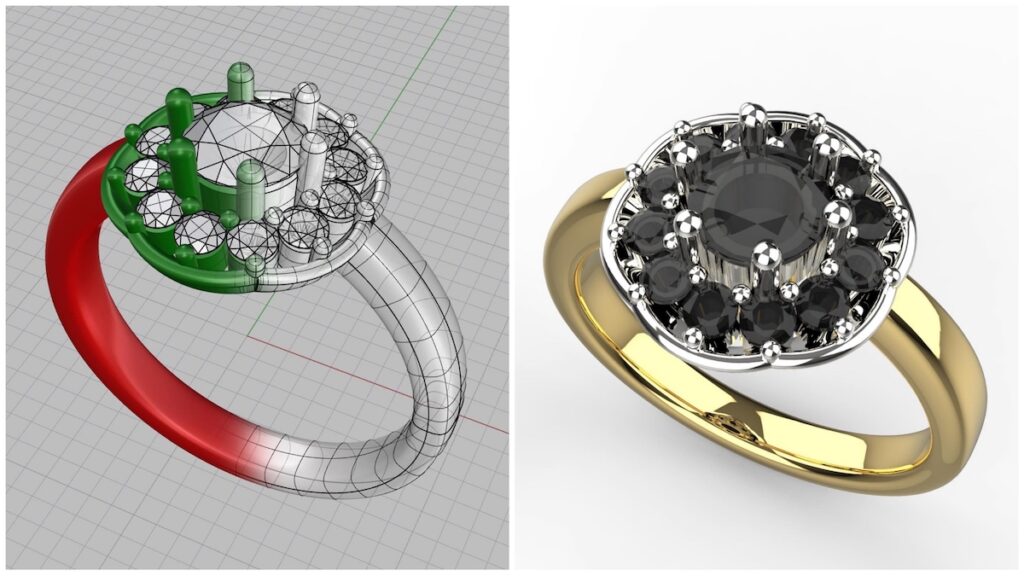

– Virtual modelling – Indian CAD artists expertly model 3D prototypes, iterating quickly based on feedback.

– Photo-realistic rendering – Brands get to visualize designs with precise materials and finishes before physical sampling.

– Design revisions – With fast turnaround, multiple rounds of changes happen digitally in days instead of weeks.

This accelerated digital workflow means seasons can shift in sync with real-time trends abd by using Indian CAD capabilities, brands can consistently deliver forward-looking, on-pulse designs.

Lower Costs for Competitive Price Points

By minimizing physical modelling and machining, India’s CAD process significantly reduces costs, while their technology-enabled efficiency lets brands maintain competitive price points and healthy margins.

With traditional methods, multiple waxes and prototypes drive per-unit expenses up. But, virtual CAD iterations cost almost nothing, and this subtracts a significant amount from production costs without sacrificing quality.

Passing these savings to customers means affordable fashion jewelry for price-conscious gen Z shoppers, and healthy margins fuel growth for brands. It’s a win-win made possible by partnering with India’s CAD experts.

Faster Lead Times for Demand-Driven Replenishment

Fast fashion cycles leave narrow windows for getting hits from runway to retail. With Indian partners’ streamlined CAD process, new designs can be turned around in just weeks after conception. Their digital workflow compresses lead times like this:

– No wax model waits – Virtual CAD revisions happen in parallel

– Direct 3D printing of molds – No lengthy machining

– Automated production setup – 3D data flows directly to equipment

– Digital quality checking – Model overlay visually verifies accuracy

By collapsing development phases, Indian CAD specialists enable quick delivery of in-demand replenishment product. Brands can chase runaway successes and leap on viral styles before they fade.

Optimized Inventory with On-Demand Production

Lengthy design phases traditionally force large batch orders to stock in advance. But India’s CAD process facilitates truly on-demand production. With an ever-growing virtual library of ready-to-produce CAD files, manufacturers can re-activate designs on-the-fly. Output scales to match incoming orders. This means minimal unmoved inventory. As consumer demand shifts, brands can fluidly adjust available styles without wasteful overstock.

Smart inventory management through Indian CAD partnerships provides sustained profitability and sustainability. The technology allows effortless scaling and pausing of production lines reacting to market needs.

Sustainable Production with AI

According to a recent study, AI technologies have the potential to cut greenhouse gas emissions worldwide by as much as 10%. The optimization and efficiency benefits made possible by AI-driven processes in a variety of industries. And including jewelry, are responsible for this notable decrease. The jewellery industry can adopt a more ecologically responsible and sustainable approach to jewellery design and manufacture by utilising AI algorithms.

By partnering with certified Indian factories, brands ensure integrity across the supply chain. The highest values of environmental stewardship and social responsibility are upheld.

Looking ahead, the collaboration between global brands and Indian manufacturers through CAD is poised to drive sustainability in the industry. By capitalizing on the strengths of Indian manufacturers in terms of skilled craftsmanship and efficient production processes, brands can curate collections that not only follow the latest trends but also adhere to sustainable practices.

Indian manufacturers, equipped with CAD proficiency, can offer quicker lead times and competitive price points without compromising on quality. This collaboration fosters a symbiotic relationship where global brands gain access to trending designs, and Indian manufacturers benefit from international exposure, resulting in a win-win scenario for both parties.

The Generational Shift: Capturing Gen Z’s Ethical Consciousness

As the industry pivots towards sustainability, the collaboration between global brands and Indian manufacturers takes on a new significance in capturing the hearts of Generation Z. This environmentally conscious generation seeks authenticity, transparency, and ethical practices in the products they choose. Indian manufacturers, utilizing CAD and sustainable practices, align seamlessly with these values, providing global brands with an opportunity to curate collections that resonate with Gen Z’s ethical consciousness.

Conclusion: A Global Tapestry Woven with CAD Threads

In conclusion, the global impact of CAD in Indian jewelry manufacturing transcends mere design aesthetics. It has become a catalyst for sustainability, efficiency, and affordability, fostering collaborations that bridge the gap between tradition and technology. As global brands and designers leverage the CAD strengths of Indian manufacturers, we witness the creation of jewelry collections that not only follow the latest trends but also uphold ethical standards, offer competitive prices, ensure quick turnaround times, and smartly manage inventory.

The future of jewelry lies in the hands of those who can seamlessly weave together the threads of innovation and tradition, and the CAD-driven collaboration between global brands and Indian manufacturers stands at the forefront of this transformative journey.

About Artisanat Overseas:

We are a product sourcing agency committed to providing global brands and designers with ethically-sourced gemstones and jewelry from India. With a strong focus on responsible practices, we ensure transparency, fair trade, and environmental consciousness throughout the supply chain. Partner with us to discover exquisite, sustainable gems and jewelry that align with your values.